A wall cutting blade manufacturer focuses on quality and effect, the advantageous wall cutting blade price is here!

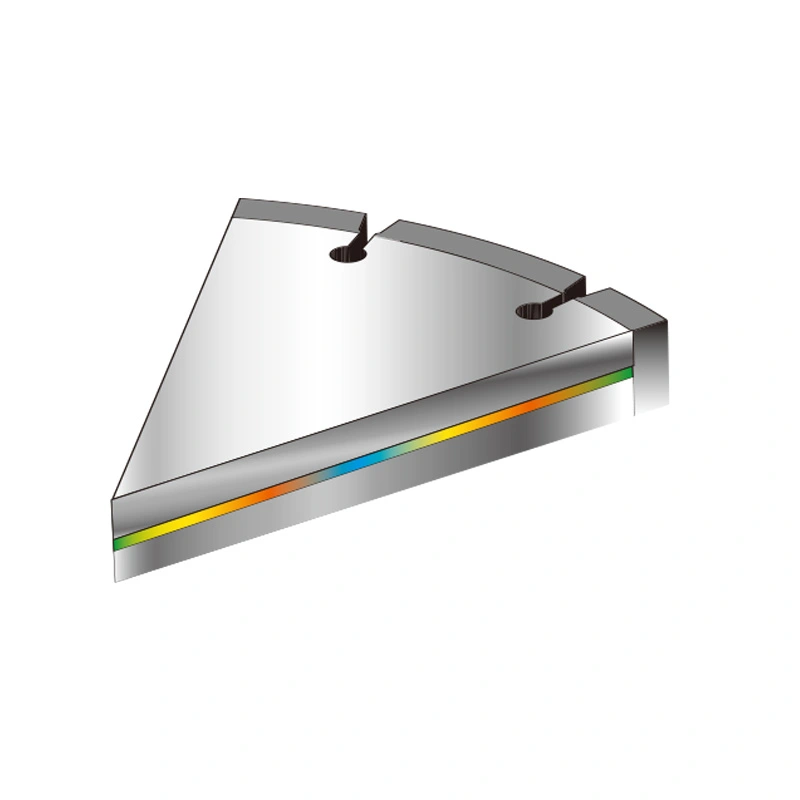

Our premium wall cutting blades are engineered with high-grade diamond segments meticulously welded onto the blade's core, designed for use with wall saws or portable concrete saws. Available in a diverse range of diameters and thicknesses—from 0.125 to 0.5 inches in thickness and 14 to 64 inches in diameter—these brick cutting blades are indispensable for a multitude of applications, including wall openings, HVAC and electrical installations, and demolition projects. As a trusted wall cutting blade manufacturer, our brick cutting blades are the epitome of precision and efficiency, ensuring clean and accurate cuts in wall constructions. With our robust production capabilities and advanced technological expertise, we are equipped to meet large-scale demands, delivering unparalleled quality and performance in every brick cutting blade. Get your wall cutting blade price now!

Wall cutting blades are available in a wide range of sizes and configurations to accommodate different cutting applications. However, some sizes are more popular than others. The most commonly used sizes of wall cutting blades are 24 inches, 32 inches, 36 inches, and 40 inches.

For smaller-scale projects and occasional use, 24-inch wall cutting blades are often sufficient. For more significant and more frequent use, the 32-inch, 36-inch, and 40-inch sizes are ideal for larger masonry materials such as reinforced concrete walls or foundations.

Other factors such as the cutting concrete blade's thickness and diamond height also affect the blade's performance and the result of the cut. The choice of the correct blade size and cutting configuration is essential to achieve the desired cut and ensure a safe and efficient cutting operation.

Versatility: As a professional diamond tool company, Buteo brick cutting multi tool blade is designed to be suitable for a variety of machines, including angle grinders, cutters and electric saws, greatly improving its application range and flexibility.

High durability: Made of high-strength alloy materials, Buteo brick cutting blade can maintain long-term sharpness and durability on various machines, reducing the need for frequent blade replacement.

Precise cutting: No matter what machine it is installed on, Buteo brick cutting blade can provide precise cutting results, ensuring that each operation can reach a professional level, suitable for a variety of complex cutting tasks.

Easy to install: Buteo brick cutting multi tool blade is designed to meet the installation standards of a variety of machines, and users can easily and quickly replace and install it, saving operation time and improving work efficiency.

Maintaining and replacing wall cutting disc is essential to optimize their performance and prolong their lifespan. Proper maintenance, such as regular cleaning and lubrication for brick cutting multi tool blade, can prevent damage to the wall cutting discs and ensure them continue to cut effectively.

Regular inspections can also detect any signs of wear or damage, allowing for early replacement before the wall cutting disc becomes unusable. Using a worn or damaged wall cutting disc can lead to lower cutting performance, increased risks of accidents, and reduced lifespan of the equipment. Therefore, it is crucial to replace the wall cutting blades as soon as signs of wear or damage appear to maintain safety, efficiency and prolong the lifespan of the equipment.

Faster Cutting Speed: The Arix segments on the wall cutting blade provide better cutting performance, resulting in faster cuts and increased productivity.

Extended Blade Life: The laser-welded Arix segments are exceptionally durable, significantly reducing segment loss. This results in a longer brick cutting blade lifespan and less frequent replacements, saving you time and money.

Reduced Chipping: The Arix segments with laser welding technology reduce chipping during cutting, resulting in cleaner cuts with minimal damage to the surface.

Improved Safety: The advanced Arix technology reduces noise and brick saw blade vibration, making the cutting process safer for the operator.

Versatility: Wall cutting blades with Arix segments can be used on a variety of materials, including reinforced concrete, brick, and stone, making it a versatile tool for different jobs.

Overall, wall cutting blades with Arix segments and laser welding offer superior cutting performance, longer blade life, improved safety, and versatility, making it an ideal choice for professionals in the construction industry.