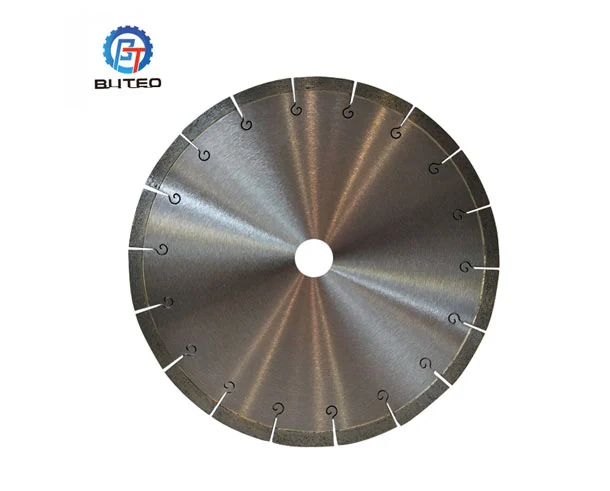

Tiles are made of fine clay, quartz sand and minerals. They are very hard and wear-resistant, so they require a special tile saw blade to cut. Buteo diamond tile saw blades feature the design optimized for table saws, ensuring efficient, chip-free, and accurate tile cutting, making them essential for various tile projects. We offer a wide range of ceramic tile blade options, including 7'' tile blade, 8 inch tile saw blades, etc, supporting your bulk purchasing plan.