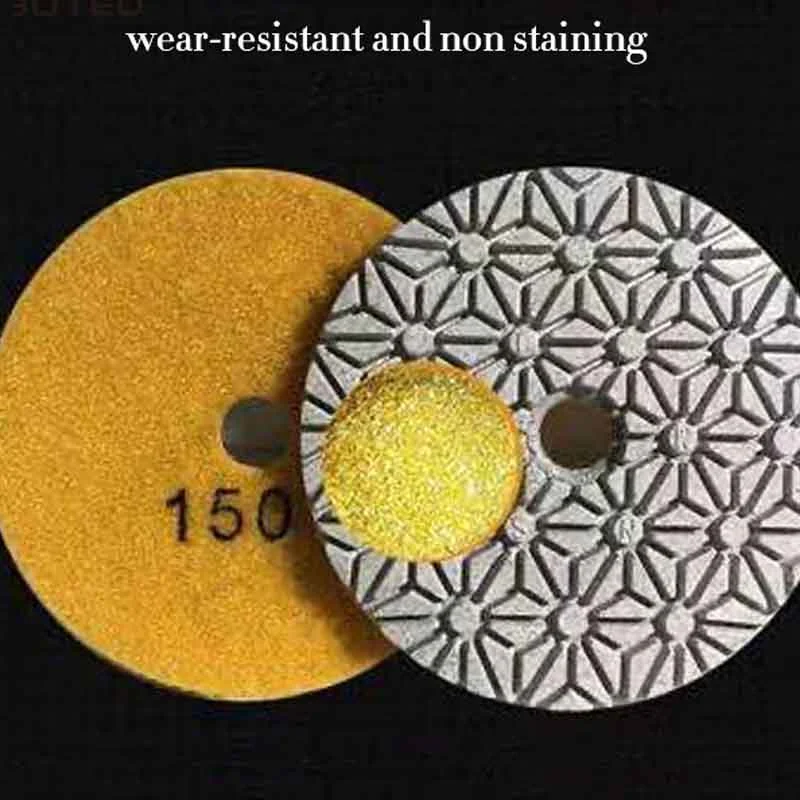

Stone Polishing Pads are essential tools for polishing & restoring natural stones like granite, marble, and more,

which usually come with diamond abrasives attached to a resin bond. The stone polishing pads are available in

various grits suitable for different applications, providing a smooth and shiny finish. Stone polishing pads are

stronger than sandstone polishing pads, which are more versatile and efficient, ideal for both wet and dry usage.

1. Coarser Grits: Coarse grits are usually in the range of 50-200 and are used for removing scratches, grind marks or for shaping stone surfaces.

2. Medium Grits: Medium grits are between 200-800 and are perfect for smoothing rough edges, leveling and preparing the surface for a final finish.

3. Fine Grits: Fine grit pads are in the range of 800-3,000 and are used for polishing the stone surface, removing any smudges or light scratches.

4. Ultra-fine Grits: Ultra-fine grit polishing pads are above 3000 levels and help in achieving a mirror-like and high gloss finish. They are used for soft stones like marble and travertine to bring out their natural shine.

The materials used in stone polishing pads include a range of abrasive particles, resins, and additives. Industrial-grade diamonds are the most commonly used abrasive particles, while resins are used as a binding agent to hold the abrasive particles in place. Other additives may be included to improve the overall performance and durability of the polishing pad. The backing material is typically made of a flexible rubber or velcro material that allows for easy attachment and removal from a polishing machine.

Recent developments in stone polishing pad manufacturing include the use of advanced resin systems for improved bonding and durability, along with new types of diamond abrasive particles for enhanced polishing efficiency. Other innovations include backing materials made from recycled materials such as rubber tires or plastic water bottles, as well as eco-friendly polishing pads that use fewer chemicals and are biodegradable.