Our ceramic tile saw blades use high-quality diamond coating to ensure precise and smooth cutting results during cutting, reducing edge damage and chipping. After precision engineering design and strict quality control, these ceramic tile blades have excellent wear resistance and long service life, and can maintain stable performance in high-intensity working environments. Wholesale or custom ceramic tile cutting blades from Buteo are a reliable choice. Available in a variety of sizes.

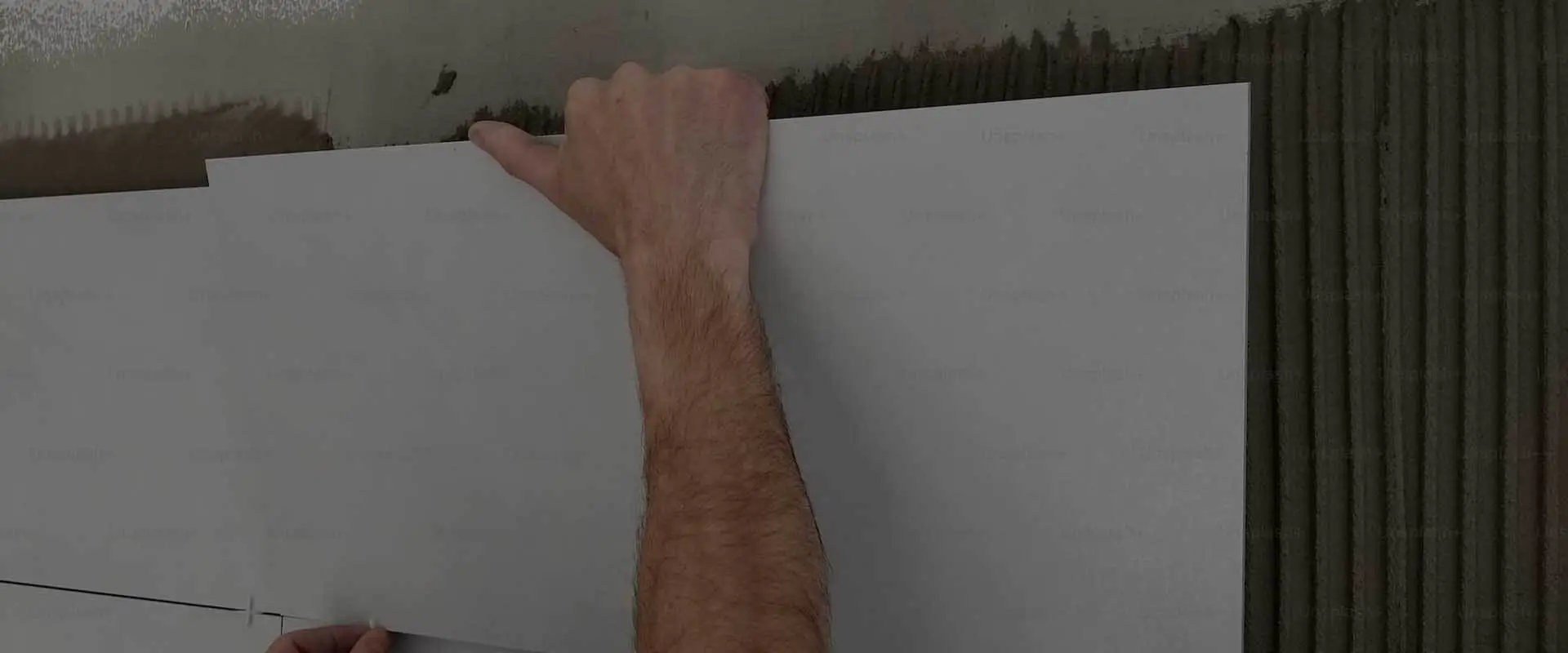

1. Ceramic Tile Saw Blades typically have a continuous rim with industrial-grade diamond or carbide particles embedded in the rim. This results in a precise and clean cut with minimal chipping, making them ideal for cutting tiles with intricate designs.

2. Ceramic Tile Saw Blades are designed to cut through even the hardest of materials, including porcelain, marble and glass with ease. They are efficient and fast, reducing downtime and increasing productivity.

3. Ceramic Tile Saw Blades are made with high-quality materials that guarantee strength and efficiency, featuring high-quality diamond or carbide particles that are resistant to wear and tear.

4. Ceramic Tile Saw Blades are versatile and can cut through a range of different materials in addition to tile, such as stone, asphalt, and sometimes even metal, making them ideal for construction and demolition projects.

Strict material selection: When we produce ceramic tile cutter blades, we first strictly screen the raw materials. Each batch of materials must undergo chemical composition analysis and physical property tests to ensure that its hardness, toughness and wear resistance meet the highest standards.

Real-time monitoring of the production process: During the production process, we use advanced monitoring systems to monitor every link in real time. Including key parameters such as temperature, pressure and cutting speed to ensure that each ceramic tile blade can maintain consistent high quality during the manufacturing process.

Multiple testing processes: Each ceramic tile cutting blade must undergo multiple testing processes before leaving the factory. Including dimensional accuracy testing, balance testing and cutting performance testing.

Simulated actual use environment testing: In order to ensure the reliability of ceramic cutting blades in actual use, we will test them in a simulated actual use environment. Including performance testing under extreme conditions such as high temperature, high pressure and long-term continuous use.

Final quality review: After all testing processes are completed, our quality review team will conduct a final review of each cutting blade. Including appearance inspection, logo confirmation and packaging inspection.

Working with ceramic tiles saw blades can be challenging, and it's important to prioritize safety. The diamond segments of ceramic saw blades can break off, causing injury. Therefore, always wear protective gear, including goggles, ear protection, and gloves. Clamping the tile during cutting provides stability and reduces the risk of the blade for tile cutter slipping. Finally, regularly check the blade for tile cutter for damage or wear, and replace it if necessary. Following these guidelines can help reduce the risk of injuries associated with cutting ceramic tiles.