Buteo concrete blades are available in a wide variety, each of which ensures excellent cutting performance and durability. Whether you need it for heavy-duty construction or fine decoration, we have the right concrete blade for you to choose from. All the concrete blades undergo rigorous quality testing to ensure stable and precise cutting results in all working conditions. Choosing the Buteo factory means experiencing the efficiency and convenience brought by professional-grade cutting tools.

Buteo's multi-tool concrete blade is not only suitable for cutting concrete, but also can easily handle a variety of materials such as brick, stone and asphalt. Its versatility makes it an all-round tool on the construction site to meet various cutting needs.

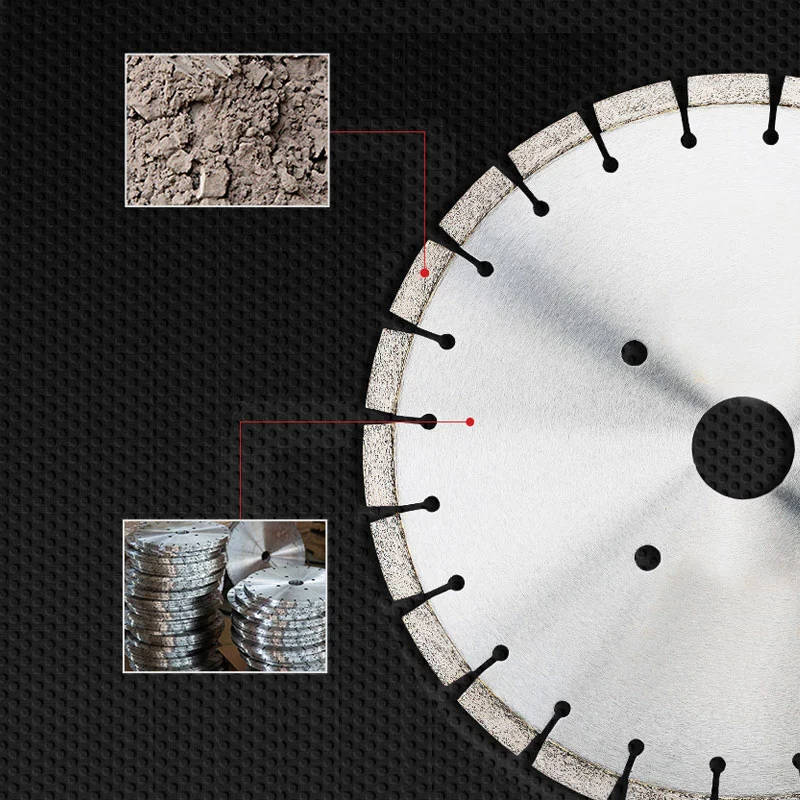

Our multi-tool concrete blade uses high-quality materials and advanced manufacturing processes to ensure its excellent durability. Whether it is frequent use or high-intensity work, Buteo's concrete blade can remain sharp and stable, reducing the frequency of replacement and reducing construction costs.

Our concrete blade is well designed to provide flat and smooth cutting results. Whether it requires high-precision detailed cutting or fast cutting of large areas, Buteo's multi-tool concrete blade can ensure high-quality construction results.

As a responsible China diamond blades factory, Buteo always puts safety first. Our multi-tool concrete blade undergoes strict quality testing to ensure its safety and reliability during use. Its design can effectively reduce vibration and noise during cutting, improving the comfort and safety of construction workers.

Cured Concrete Saw Blade

Buteo cured concrete saw blades are specifically engineered for cutting fully cured concrete, offering outstanding cutting performance and durability. These concrete blades maintain sharpness and stability even in high-intensity cutting tasks, ensuring smooth and precise cuts.

Green Concrete Blade

Buteo green concrete blade, designed for cutting newly poured, not yet fully cured concrete, ensures high efficiency and low wear during the cutting process. These saw saw blades for concrete minimize chipping and cracking, delivering smooth and precise cutting results.

Soft Cut Concrete Saw Blade

Buteo soft cut concrete saw blades are ideal for early-entry cutting of concrete, allowing you to make control joints within hours of finishing. These cutting concrete blades minimize the risk of random cracking and ensure clean, straight cuts, perfect for projects requiring early intervention.

Proper storage of concrete blades is essential to ensure their longevity and optimal performance. Here are some steps for concrete blade storage:

Clean the blade: Ensure the concrete blade is clean and free of any debris, dust or moisture.

Protect the blade: Use blade protectors to prevent the blade from being damaged or scratched while in storage.

Store in a dry place: Store concrete blades in a cool, dry place to minimize the risk of corrosion.

Store vertically: Keep the blades stored vertically or flat to prevent shape deformation and distortion.

Label and organize: Label the blade protectors or boxes with the size, type, and date of the blade. Organize the blades by size and type for ease of use.